Information - Pressure tanks - hydrophore tanks

Pressure tanks – selection and operation

Pressure tanks – selection and operation

Author Akvedukts

The pressure tank is one of the most important components of the booster set or pumping station (water pump with pressure tank - hydrophore and pressure switch). Its proper selection and operation ensure safe and durable operation of the water supply system and water pump. Pressure tanks, which are also called bladder autoclaves, hydro accumulators and hydrophores, are used in water supply systems for both private homes and industrial facilities. How to choose them and how to properly maintain?

Pressure tank (bladder autoclave, hydro accumulator, hydrophore) - tank for water storage, for equalization of pressure in water supply system, prevention of hydraulic shock, reduction of pump starting times and ensuring continuous work of pump automatics. It is a hydro-pneumatic tank, which simultaneously contains air and water separated by a flexible waterproof membrane. The membrane can be in the form of a bag (bladder) or built perpendicular to the wall of the tank, separating the water and air parts in the tank. The bag membrane (bladder) for small pressure tanks will be flanged on one end of the tank, while for larger pressure vessels it will be attached to both ends of the tank. The bladder is replaceable. A perpendicularly mounted diaphragm is not replaceable, but such pressure tanks (hydrophores) require much less pre-charge pressure or backpressure checks.

Pressure tanks are also called bladder autoclaves, hydrophores and hydro accumulators. The word hydrophore comes from the Greek word χιδροφόρος, which means "aquifer." Booster set is often called a hydrophore, because one of its main components is a hydrophore, although the main function - water supply is performed by a pump and hydrophore only equalizes the pressure changes in the system. It is important not to confuse the pressure tank with the expansion tank, as the pressure tank is for water supply and the expansion tank is for heating systems.

Selection of pressure tank

To choose a suitable pressure tank, you need to determine the required volume of the tank and pre-charge pressure. It should be understood that tank volume does not mean the amount of water stored in the pressure tank, but the total volume of air and water in that tank.

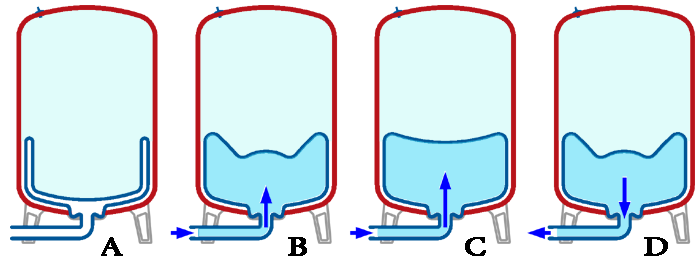

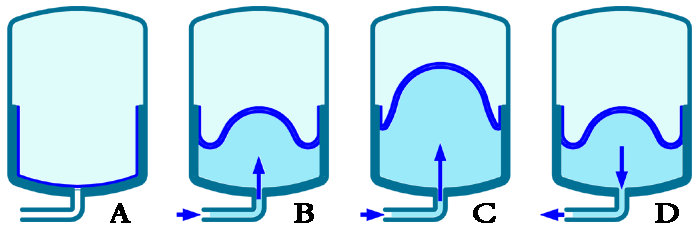

The figure shows the position of the single-flange bladder in the tank when (A) there is only air pressure or pre-charge pressure, (B) when water is being supplied to the tank at a pressure greater than air pressure, (C) when water is being supplied to the tank at maximum pressure and the pump is turned off, (D) when the water faucet is opened and the tank uses air pressure to pressurize the water into the system. No matter how high the water pressure is, it is impossible to completely compress the air cushion in the tank, so the amount of water in the pressure tank will never be more than half of its volume. The bladders in large hydrophores are connected to the tank at both ends. A pressure tank with a perpendicularly mounted diaphragm, shown in the figure below, has a similar operating principle.

Read more about types of bladders / diaphragms and their replacement

What should be the pre-charge pressure

If the air pressure in the pressure tank (hydrophore) is equal to or greater than the maximum pump pressure, no water will flow into the pressure tank at all because the water pressure will not be sufficient to compress the air cushion on the other side of the diaphragm. To ensure automatic operation of the pump in the booster set, the calculation of the pre-charge pressure in the pressure tank is simple - it should be 0.2 bar (0.2 atm) lower than the pump ON pressure. For example, if the start pressure of the pump is set at 2.0 bar (2.0 atm), then the pre-charge pressure in the pressure tank should be 1.8 bar (1.8 atm). Pre-charge pressure of pressure tank

How to select the volume of the pressure tank

In some cases, a small pressure tank of 5-8 liters is sufficient to prevent water hammer or to equalize the pressure in systems with slight pressure fluctuations. A pressure tank of 20-25 liters will be sufficient to ensure the automatic operation of the water supply system of a single-family house (private house). For a slightly larger system, such as the water supply of a two-family house, or a private house with outbuildings, it would be better to install a pressure tank of 50 liters. If the water supply system is larger, it may be necessary to calculate the volume of the pressure tank (see Pressure tank sizing Calculations)

Where to install the pressure tank

Pressure tanks of small volume (5-18 liters) do not create a lot of weight, so they can be connected directly to the pipe system, with or without a wall mount. Larger pressure tanks are placed on the floor. Horizontal pressure tanks are usually equipped with a shelf on which the pump can be placed, while vertical pressure tanks take up less space because they are designed as a vertical cylinder. The figure shows ELBI pressure tanks with a bladder and GWS pressure tanks with a fixed diaphragm installed perpendicularly.

|

|

| Pressure tanks with bladder | Pressure tanks with diaphragm |

The pressure tank can be installed anywhere in the water system, as it is hydraulically unified. In order to ensure its more accurate operation, it is recommended to place the pressure switch and other automatic pump operation control near the pressure tank (see Instalation of pressure tank).

Operation and maintenance of pressure tanks in the water supply system

In recent years, pressure tanks have become available that, according to the manufacturer, require no or very little maintenance. In the Akvedukts range these are pressure vessels manufactured by GWS, made of steel or composite material and with a perpendicularly integrated, non-replaceable diaphragm.

Pressure vessels with replaceable diaphragms (bladders) must have their air pre-charge pressure checked and, if necessary, corrected during operation. The service life of a pressure tank with a bladder depends on the water quality and the use of the system. The more often the pump is started and stopped daily and the more solid impurities in the water, the more often the diaphragm may have to be replaced. On average, the life span of a pressure tank bladder is 3-5 years. In cases where the water quality is poor or the hydraulic conditions are difficult, we recommend installing a pressure tank with a replaceable diaphragm - bladder (see Checking and Correcting Pre-charge Pressure).

Pump problems caused by pressure tank

The quality of the automatic operation of the booster set also depends on the pressure tank. If the pressure tank is damaged, the pressure in the system fluctuates rapidly and the pressure switch responds accordingly - the pump starts and stops frequently and jerkily. The most common problems of pressure tanks:

- Insufficient pre-charge pressure: for a variety of reasons, the air pressure pumped into the tank decreases and must be replenished (see Checking and Adjusting Pre-charge Pressure).

- Ruptured diaphragm or bladder: Over time, the diaphragm will wear out and may lose its tightness (see Bladder Inspection and Replacement).

- Leaking pressure tank walls: steel tanks corrode when exposed to moisture and over time can begin to rust, creating small holes in the tank walls through which the air pressed into the tank escapes. In this case it is necessary to completely replace the pressure tank.