Information - Water pumps, booster sets

What you need to know when choosing a deep well pump

What you need to know when choosing a deep well pump

Author: Akvedukts

When creating a new deep well (drilled well, borehole well, artesian well), the selection, delivery and installation of the water pump can be entrusted to the well operator. In this way, there is no worry about installing the pump and the responsibility of water supply is in the hands of one person. However, there are cases when you want to purchase the pump yourself, or the well was built a long time ago and you need to install a new pump or replace an existing pump that no longer works. In such cases, there are a few simple but very important things to know in order to buy a deep well pump that suits your needs and the capabilities of your well .

The three most important things for choosing a deep well pump

In order to choose the right well pump, you need to know three important things - (1) information about the well, (2) information about consumption, and (3) preferences, if any, for the technical performance of the pump.

1) Information about the well:

- inner diameter (this may vary depending on the depth of the hole)

- total depth

- flow rate (amount of water that can be obtained from a well in steady consumption mode)

- static water level (water level in a borehole when water is not taken from it)

- dynamic water level (water level in a well when an amount of water equal to the discharge is taken from it)

All these data are indicated in the deep well passport prepared by the well driller. In cases where you are buying a property with a deep well, find out if it has a passport. If, for some reason, the well passport is not available, we recommend that you contact the drilling companies and find out the cost of obtaining this information and creating a passport.

- The location of the borehole and the diameter of the pipeline connecting the borehole to the facility being supplied

2) Information about the water supply facility:

- What is the planned water consumption (e.g. single family building)

- The highest floor of the building where water consumption devices are located

- Distance from the well to the supported object

- If the borehole is located lower than the building in the terrain, then the difference in height between the borehole head and the foundations of the building

- The diameter of the pipeline from the well to the supplied object (if the pipeline is not laid, then its diameter should be determined according to the planned consumption)

- Available voltage and power for the water pump (single phase or three phase)

3) Requirements for technical performance

Based on the above information, you can already choose a water pump that will work according to the intended purpose and according to the water flow rate of the deep well. The choice of pump will be even more appropriate if you inform the seller of your wishes regarding the technical performance of the pump:

- Preferred type of control - the downhole pump will work electronically and change power depending on consumption, or it will be turned on / off by a pressure relay signal

- Available voltage to operate the pump (single phase or three phase)

- Other preferences for the pump, such as casing material, impeller material, etc

If you need to replace a pump that has served its time and you were satisfied with the performance of the previous pump, then to buy a new pump, it will be enough if you tell us the diameter of the existing pump (mm or inches), voltage information (single phase or three phase) and three performance parameters: productivity (l/ min), pressure (bar, m) and, if known, power (kW). This data is usually indicated on the pump nameplate.

Why do you need to know the borehole parameters?

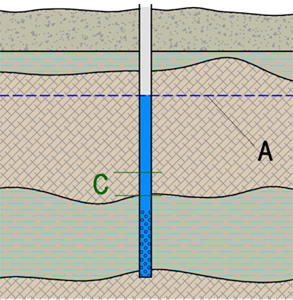

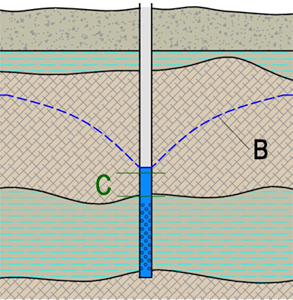

The downhole pump is installed in the well at a safe depth. A safe depth is one where there will always be water. When water is not drawn from the well, the well gradually fills and the water settles at a height called the static water table (picture left/top). The static water level equals the pressure in the aquifer from which the water is taken (pressure line A). When the pump starts drawing water from the well, the pressure near the well decreases (pressure curve B) and the water level in the well drops accordingly. If the water pump takes the maximum allowed amount of water from the well (well discharge), then the water level will drop to the dynamic level (image right/bottom). The difference between the static and dynamic water level is several meters, sometimes even a few tens of meters.

The sump pump must be installed at least 2 meters below the dynamic water level, otherwise it may start to idle (without water). As the water level decreases, the height at which the water pump must push water increases accordingly, so the pressure height of the pump should also be calculated not from the top of the well pipe or the static level, but from the dynamic level. The sump pump must be located above the well filter. The well diagram shown in the picture shows the safe zone (C) for placing the pump in the well - below the dynamic water level and above the filter area of the well.

The productivity of the borehole pump must not be greater than the flow rate of the borehole. Even if the pump will be installed in a safe place - below the dynamic water level, if it pumps more water from the well than the flow rate of the well, two risks will arise:

- collapse of the aquifer - particles of the aquifer (sand, etc.) will increasingly enter the well, which will cause damage to the water pump, blockage and burning of the electric motor; mechanical damage to the well structure may be caused

- water level falling below the dynamic level – if the water level falls below the level where the pump is located, the mechanical part of the pump and the electric motor will be damaged.

Therefore, the parameters of the well should be known in order to correctly determine the required pump pressure and not to choose a pump with too high productivity. If these data are not known, an appropriate pump selection is not possible.

What if borehole data is not available?

The only safe decision is to contact a well drilling company that can perform tests and prepare the necessary well information. After receiving the prepared information, choose the appropriate pump.

You can be interested in the capacity of a deep well pump installed in a neighboring well, you can install a pump with as little consumption as possible, or you can try to determine the necessary parameters of the well yourself, but in all these cases, the risk of choosing a pump remains solely with the buyer. A technically knowledgeable and responsible seller will not recommend a downhole pump model in such situations. It should be noted that in the pump service, problems caused by improper selection of the pump can be easily determined by the presence of sand or other rock particles in certain parts of the pump. In such cases, the warranty terms are not applied and the repair costs (if repair is possible) must be covered by the buyer.

Other recommendations

When buying a deep well pump, it is necessary to purchase not only pump installation equipment, but also pump electric motor protection equipment (especially important for deep well pumps with a three-phase electric motor).

A vibratory pump must not be installed in a deep well, as the vibrations generated by it have a negative effect on the structure of the aquifer and the tightness of the well pipes.

If the dynamic water level in the deep well is not lower than 8m, consider the possibility of installing a conventional water supply pump, which will be a more economical solution.