Information - Water pumps, booster sets

Water booster sets – operation and maintenance

Water booster sets – operation and maintenance

Author: Akvedukts

See the offer of water booster sets in the Akvedukts E-warehouse

A water booster set is a water supply unit consisting of a water pump, a pressure tank and a relay or automation that turns the pump on or off depending on pressure changes in the water supply system. The pressure tank is necessary so that the water pressure changes in the system are not instantaneous - it ensures smoother operation and longer service life of individual system devices and equipment (pump, pressure relay, pipeline connections), as well as the entire system.

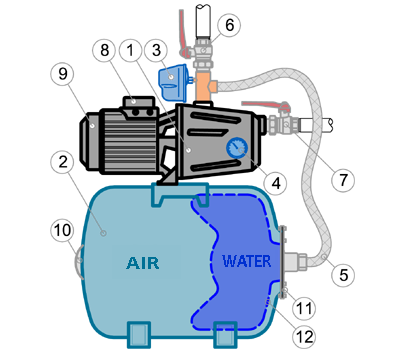

1 - water pump, 2 - pressure tank, 3 - pressure relay, 4 – pressure gauge, 5 - flexible connection to the pressure tank, 6 - ball valve in the pressure line, 7 - ball valve in the suction line (optional), 8 - pump electrical connection box (for pumps with a single-phase engine, the capacitor is located here), 9 - pump motor cooling fan cover, 10 - pressure tank air valve (usually located under the cover), 11 - pressure tank membrane flange, 12 - pressure tank membrane.

When choosing a water booster set, two important factors should be taken into account - the requirements regarding water flowrate and pressure, and the ability of the water source (deep-well or grote well) to provide the required amount of water (debit). If the amount of available water is sufficient to meet consumption needs, the water booster set is selected according to the required flowrate and pressure, while if the water resource is limited, the water pump is selected that does not exceed the flow rate of the water source.

For small water booster sets (performance up to 30 l/min at up to 3 bar), a pressure tank size of 20-25 litres is sufficient. The pressure tank volume of a water booster set shall be determined by the operating flow rate, the pump switch-on frequency and the operating pressure of the system ( Sizing a Pressure tank ). The volume of water storage is not a factor in determining the pressure tank volume of a water booster set, but when installing a water pump in areas where frequent power outages may occur, it may be justified to select a pressure tank with a significantly larger volume than is necessary for the safe operation of the system only. It should be remembered that most of the volume of a pressure tank usually contains air, not water. More about the operation and selection of pressure tanks here. The third most important component of water booster sets is the pressure relay. Pressure relays can be mechanical and electronic. Mechanical pressure relays are cheaper and also accurate enough. It should be taken into account that the springs and contacts included in the construction of mechanical pressure relays wear out and periodically this relay must be replaced. If the water booster set has a mechanical pressure relay, then it must also be equipped with a pressure gauge for determining the pressure in the water supply system and for adjusting the pressure relay (see: adjustment of mechanical pressure switch ). For electronic pressure relays, the pressure gauge is built into the device and does not require the installation of a separate pressure gauge (see: digital pressure relays), however the service life of electronic pressure relays directly depends on the chemical properties of water and the amount of mechanical impurities in the pumped water.

Operation and maintenance of water booster set

The water pump itself is maintenance-free. The most important task is to perform a pre-charge pressure test in the pressure tank periodically, for example once every six months. This check becomes especially important in cases where the pump shut-off pressure is 3.5 bar and more. The exception is water booster sets equipped with a special pressure tank that does not need to be pressure tested ( GWS pressure tanks ). If necessary, the pressure switch must be adjusted during maintenance period of the water booster set.

Checking the pre-charge pressure of the pressure tank with an air pressure gauge

After operating the water booster set for several years, it may be necessary to replace the seal or bearings of pump. The pump's single-phase electric motor will need to periodically replace the capacitor, as it is a product with a limited number of operations. Over time, the contacts of the mechanical pressure relay may weare out, in which case the pressure relay must be replaced completely (a digital pressure relay can be installed). The bladder of the pressure vessel also may wear out, or a hole in the wall of the pressure vessel may rust, in which case the bladder must be replaced or the entire pressure tank replaced respectively.

The most common malfunctions of water booster set and their elimination

Operating errors and breakdowns of water booster set tend to be similar, regardless of the manufacturer of the pump, pressure tank or pressure relay. In the table below, we have collected the most frequent problems and recommendations for solving them. We will not consider such situations as a pump not connected to electricity, a frozen pump, and similar. Problems that tend to occur during the installation of the water booster set are described in the installation instructions, which we always recommend to read in full before installing the water pump. If you cannot take on the troubleshooting or repair, call in a skilled professional, as pump malfunctions are often related to the entire water supply system and not to the components of the booster set itself.

Water booster set operational malfunctions and their solutions:

| No | Malfunction | Solution |

|---|---|---|

| 1 | The pump humming but does not start rotation | 1. If the fan of the pump motor rotates freely ( check it when the pump is disconnected from the power supply ), the culprit could be the capacitor - a white cylinder with two wires) located in the pump electrical box. Check the size of the existing capacitor in µF (microfarads) and replace it with a new one. |

| 2. If the pump motor fan does not rotate, remove the fan protective cover to allow free access to the fan blades located on the pump rotor shaft. Try to move the axle by quickly tapping the axle. Take care not to damage the fan blades during these steps. If these steps do not help, the pump should be taken to a service workshop. | ||

| 2 | The pressure relay twitches when the pump turns on or off | See the causes of pressure relay operation errors |

| 3 | When the pump turns off, the pressure relay turns on and off several times, the pressure reading on the pressure gauge changes rapidly | An air bubble in the suction pipe, which affects the filling of the pipe with water and thus the pressure readings. Gotta get rid of the bubble. |

| 4 | The pump turns off as soon as the water tap is closed and turns on as soon as water consumption resumes | 1. There is not enough pre-charge pressure in the pressure tank. Must be checked and corrected ( pre-charge pressure check ) |

| 2. If, when pressing the air valve of the pressure tank, water flows through it, the bladder of the pressure tank must be changed (see bladder replacement ) | ||

| 5 | The pump does not turn off, it continues to work if all taps are closed. | 1. Make sure that all taps are really closed and there is no leakage in the system - turn off the power supply to the pump and watch the pressure gauge reading. If the pressure drops, there is an open tap or a leak in the system. |

| 2. See also the causes of pressure relay operation errors | ||

| 6 | The pressure relay switches the pump on/off only when the relay housing is punched | The contacts of the pressure relay are worn out. The pressure relay must be replaced |

| 7 | The pump sometimes shuts off automatically, but sometimes it doesn't shut off and continues to work. | The relay settings must be changed or the pressure relay must be changed. The problem must be fixed as soon as possible, because long-term operation of the pump without water consumption causes serious damage to the pump. |

| 8 | The pressure reading on the pressure gauge drops rapidly after the pump shuts off | Leakage in suction or pressure line. You can determine if the leak is directly in the suction or pressure line, if after the pump is turned off, close the tap immediately behind the pump (to check the suction line). If the pressure drops, look for a leak in the suction line (pipe connections, check-valve); if the pressure does not drop, the leak is in the pressure line. |

| 9 |

The pump periodically turns on by itself, although the taps in the system are closed. |

After the pump is turned off, the pressure gauge should be observed until the next time pump is turned on - if the pressure drops, there is a leak in the suction or pressure line. You can determine if the leak is directly in the suction or pressure line, if after the pump is turned off, close the tap immediately behind the pump (to check the suction line). If the pressure drops, look for a leak in the suction line (pipe connections, check-valve); if the pressure does not drop, the leak is in the pressure line. |

| 10 | The operation of the water pump has become significantly louder than usual | 1. Damage to the pump bearings, the bearings need to be replaced in the specialised service |

| 2. Damage to the pump impeller or ingress of a debris into the pump's working chamber | ||

| 11 | The water pump draws air, air bubbles appear in the water | 1. Leaky connections in the suction line |

| 2. A decrease in the water level in the well, a clogged suction screen, or an increase in pressure drops in the suction pipeline - in such situations, the cause of bubbles is cavitation, which can cause damage to the pump as well | ||

| 12 | The pump is no longer able to provide pressure as usual | 1. Problem in the pressure line – a water supply tap is open or the system has a leak |

| 2. Suction line – non-hermetic connections, air is drawn in, creating an air bubble in the pump. | ||

| 3. Water pump – the pump has been operating for several years, the impeller or ejector is damaged. | ||

| 4. The water level in the well has dropped | ||

| 13 | When you turn on the water tap, the pressure drops rapidly | Pre-charge pressure and bladder testing should be performed |

| 14 | The pump often turns on, but only for a short time | 1. Check-valve problem in suction line |

| 2. Small leak in supply (pressure) line | ||

| 15 | Air cannot be pumped into the pressure tank | The bladder of the pressure tank is stuck to the wall of the tankl. All the water must be drained, the bladder flange must be unscrewed and it must be pushed from the tank wall (see also Bladder replacement ) |

| 16 | After a long period of non-use (after a night or a longer period), the first start-up of the pump starts with the presence of air. During regular use of water, the problem is not observed, after the next night the problem recurs | The situation occurs when the check valve is not at the end of the suction line, but closer to the pump. A small leak between the water source and the check valve, resulting in air entering the suction pipe. Leakage must be prevented. |

| 17 | The shower has variable pressure and water temperature. | See the description of setting the pressure relay . |

We urge you to assess the knowledge and capability of troubleshooting the pump unit yourself. Always disconnect the water booster set from the power supply before working on it! Remember that it is more reliable to call an experienced specialist, who will have the necessary tools and equipment for work.

Akvedukts service provides maintenance and repair of water pumps and water booster sets of the brands represented by "Akvedukts" in its service facilities, as well as availability of spare parts and equipment for these devices.